Information details

Five advantages of tungsten carbide insert coating

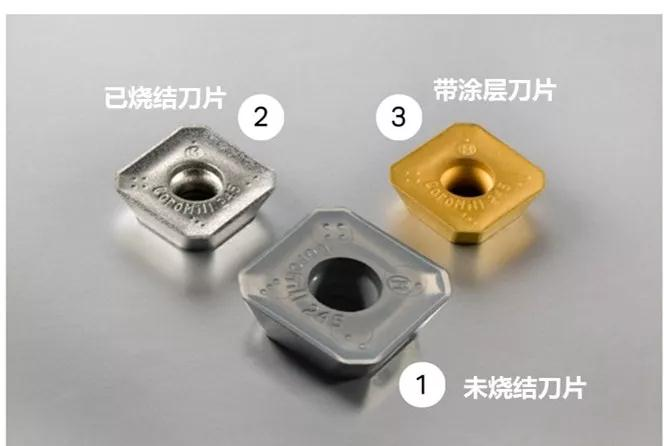

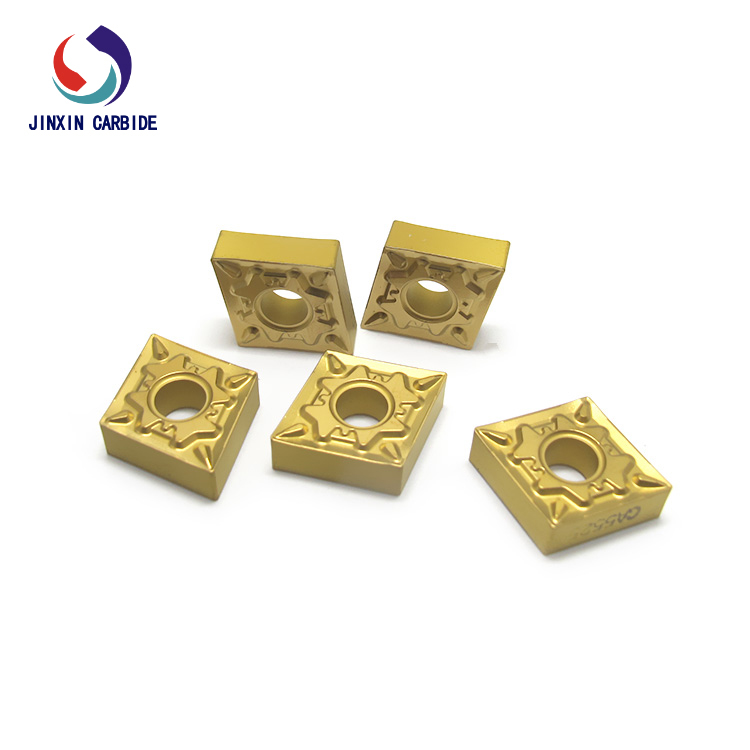

Tungsten Carbide cutting tools are the most widely used cutting tools in the machining market. This kind of tools significantly improve the productivity level of metal cutting process, thus greatly reducing the manufacturing cost of daily articles.At present, a variety of advanced coating technology and coating materials have appeared in the market. Tungsten Carbide coated tool head is one of the main products of Zhuzhou Jinxin, and the coating can be coated with high quality wear-resistant layer on the common substrate material to extend the life of alloy tool and improve the cutting parameters.

Tungsten carbide insert coating are summarized as follows:

1, the surface of golden TiN can reduce friction and provide wear identification effect

2, the special structure of Al2O3 deposition layer has the best thermal barrier performance, to ensure the high speed dry cutting, blade matrix plastic deformation resistance.

3, TiCN layer has the performance of abrasive wear resistance, so that the blade rear surface wear resistance is the strongest.

4. Using gradient sintering technology, the impact resistance and wear resistance of the cutting edge are enhanced, so as to improve the anti-damage ability of the cutting edge.

5, containing special crystal structure of carbide, improve the carbide head matrix red hardness, strengthen the blade high temperature resistance performance.

Zhuzhou jinxin offers all kinds of cemented carbide cutting tool type, and helps to choose the right carbide blade number, and support of non-standard custom, professional custom manufacturer, advanced processing equipment, processing ability is strong, there are a large number of various industries custom successful cases, covers an area of 12000 square meters, collectivize, diversified production lines, supply ability, meet the needs of customers worldwide.